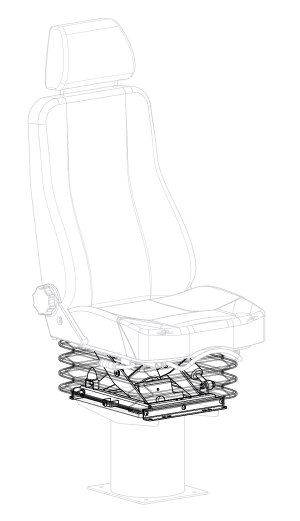

All seat base variants have bellows made of highly flame-retardant rubber or silicone mixes.

These bellows protect the users from injury caused by unintentional intervention in the mechanics, prevent the system becoming soiled and also look good.

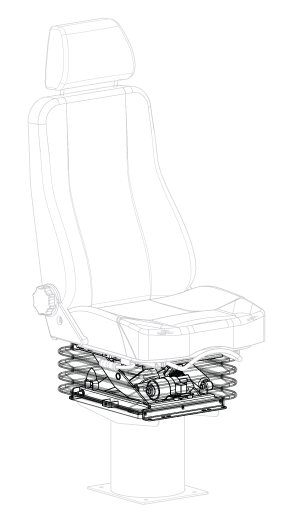

The seat bases themselves work based on a proven scissor principle. Thanks to their extremely stable position in maintenance-free PTFE plain bearing bushings and the solid design of all parts, they are torsion-resistant and highly durable even under extreme conditions. Slide rolls made of polyamide also underscore this effect.

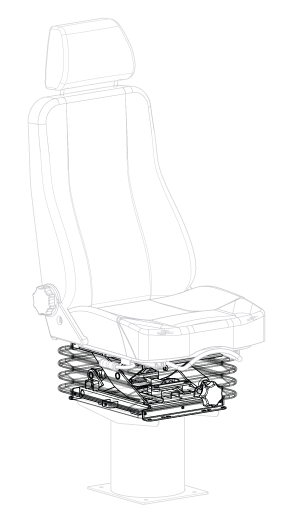

Mechanical suspension system

The mechanical suspension system is equipped with a dual-action hydraulic shock absorber. The seat is set to the respective weight of the driver between 55 kg and 150 kg by means of a rotary handle attached at the front in the driving direction. The natural frequency is approx. 1.5 Hz, the spring path is 80 mm, of this 30 mm status suspension when set to the respective driver’s weight.

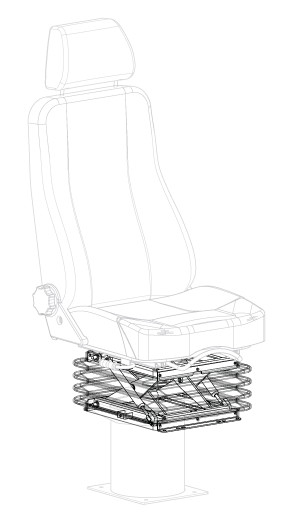

Pneumatic-supported height adjustment

The seat base is equipped with locking and/or cushioned locking pneumatic springs that are designed to overcome the seat’s own weight by means of the control handle so that the seat is moved upwards from the lower position. To achieve this, the seat needs to be relieved of the driver’s weight. To lower the seat, the user must relieve the load and activate the control lever at the same time. The stepless adjustment range is 130mm. Within this setting range, the system blocks in any position when the activation handle is released. The customer can request the adjustment range to be limited.

Height and inclination adjustment

The mechanics are part of a separate component that is placed below the seat cushion; it is also protected by real leather bellows to prevent injury to the user or soiling. With this inclination adjustment, the seat surface (respectively the total upper seat part) can set bet between effective -6° (tilting forward) to +6° (tilting backward) It is operated by means of two control levers attached to the side.

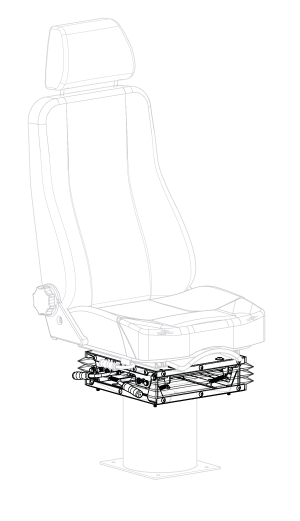

Air suspension system (compressed air is provided by the vehicle)

The air suspension system installed in the seat base has a dual-action hydraulic shock absorption. The natural frequency is 1.1 Hz to 1.5 Hz depending on the air filling and driver’s weight. The air is connected via a flexible compressed air hose with the dimensions 6×1 mm. The function and durability of air-sprung MÖVE driver’s seats are guaranteed, if there is a pressure of 5.5-10.0bar on the vehicle side. In reaction to the solids in the compressed air, the purity class 1 to 4 according to ISO 8573-1 applies. The spring hardness of the system and the height of the seat are adjusted via the buttons attached to the right or left of the seat cushion. If the air supply is interrupted in the vehicle, the selected seat position is maintained; in case of leaks in the suspension system, there is a throttle valve for delayed air discharge from the air spring.

Air suspension with integrated small compressor

If there is no compressed air for the seat in the vehicles, e.g. in trams, the seat base can be equipped with an integrated 12 or 24 Volt DC small compressor that assumes the air supply function.